Process

Old instrument panel cluster

New instrument panel by Baker Air that is much cleaner and easier to see than before.

When we rebuild the Super Cub, it is standard for us to install all new wiring, switches, and circuit breakers.

Stainless steel firewall for good looks and extra safety from an engine fire.

Boot cowls are re-skinned and the firewall is replaced.

All parts are sandblasted, inspected, and primed and repainted to look like new. Floorboards are replaced with new also.

Fuselages are also sandblasted, inspected, and primed and repainted with epoxy paints to ensure long lasting protection from corrosion.

All cowling is replaced to look like new again.

All tail feathers are sandblasted, inspected, and primed and painted with epoxy paints.

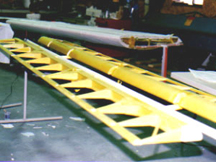

Wings are repaired to new and chromated for corrosion protection.

Flaps and ailerons are also repaired to look like new and chromated.

All airplanes are test fitted together to ensure the best quality when the rebuild is completed.

All airplanes have new interior panels, plexiglass, and contain many mods to improve performance and/or safety of the Super Cub.

We paint the interior panels light gray for added interior brightness. We have been told many times that are airplanes are better than new.

All airplanes are covered with the Poly-Fiber process.

Airplanes are top coated with a highly flexible polyurethane paint that is very shiny and chemical resistant to ensure good looks and long lasting fabric.